Featured on FacilityCare in April 2015.

Utilizing KaiNexus – a cloud-based platform that allows cross-office access to improvement projects – to identify and track an opportunity for improvement (OI) is an intuitive way to manage enhancement efforts firm-wide.

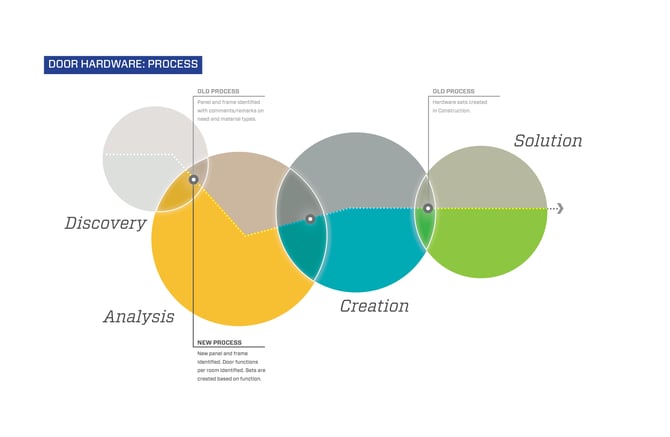

Recently, studio members identified an OI regarding the door hardware specifications (specs) process. With the old process, designers, using Revit, classified door information as instance based, where the parameters were entered as per door requirements. The door family, Single-Flush.rfa, for example, was comprised of a solid core wood panel with a hollow metal frame and any comments or remarks noted during user group meetings. These comments and remarks were later used to create and define door hardware sets, which comprised hinges, latches and other hardware needed for door functionality.

Additionally within the old process, the door types and the hardware sets were independent of one another. As a result, any requested changes to a specific door required a designer to edit, within the Revit model, each door family in order to revise each hardware set for every individual door affected by the changes. For instance, if a client requested a different hinge for patient room doors and the facility has 120 patient rooms, designers had to create a new hardware set before editing each of those 120 doors individually.

Now, rather than using instance-based door families, designers are creating performance-based doors that are based on the room function and requirements. For example, a designer would duplicate the Single-Flush.rfa in the Revit model as “Exam Room Door” and use it at all exam rooms in the model. Moreover, all doors that require a card reader, keypad or other electronic locking mechanism have a tag in the architectural drawing. These tags enable an electrical engineer to see, on the drawing, doors that require low-voltage or other source of power.

During our Analysis phase, the Project Architect will gather information relative to setting up the project standards. Asking questions regarding a client’s typical door types and hardware brands, how specific doors should function, required types of security, etc. ensures the correct standards are documented from the beginning. After successfully using the new process in two projects, Array chose to implement it on all future projects.

Understanding the client’s specific requirements is especially important in healthcare facilities, which have a variety of unique door opening applications and specific door hardware requirements to match. Additionally, building codes – federal, state and local – affect a firm’s hardware choices.

Moreover, once identified, if changes to a door, such as a patient room door, are required, individual patient room door changes are not necessary. When all patient room doors are identical, rather than editing 200 doors, the design change happens once within the drawing, decreasing potential errors. While there are instances of different door types in the same room, descriptive labeling addresses that issue.

Toilet rooms, for instance, often require different door types. In healthcare design, staff toilet rooms and patient toilet rooms require two types of doors. A patient toilet room requires emergency rescue hardware. If the patient is in distress and falls against the door, or is attempting to prevent staff from entering, the door has to swing out into the patient room. Staff toilet rooms do not have the same stringent requirements and codes.

By using performance-based doors, the hardware consultant has all of the necessary parameters to build their hardware sets. Knowing that patient toilet rooms require emergency rescue hardware, a consultant may recommend a double acting pivot hinge and an emergency doorstop. With this recommendation, the double acting pivot hinge allows the door to swing either way, while the door stop converts it to a single acting door for daily use.

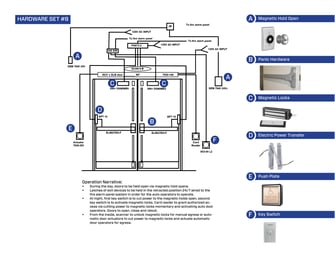

Identifying door sets by their function is not only beneficial during the specs creation, but also when coordinating with electrical engineers and for reference in user group meetings. When the main concern is security and safety, identifying user needs is essential. Each healthcare facility has different security requirements – tightly locked down, selectively secure, privacy locks, restricted access, controlled egress, etc. – that depend on variables such as the type of rooms along a corridor or the overall type of facility (behavioral health vs. outpatient for example).

Behavioral health doors, for instance, require varying levels of security throughout the facility. From the hinge selection to the lock function, the design team needs to collect important information before creating the door hardware sets. With patient safety as a main concern, every detail is critical. Continuous hinges with hospital tip (sloped) on patient room doors make it difficult to wrap or hang things from them. Emergency door sensors alert staff when a heavy item is hung over the door. When selecting a lockset, it is crucial that patients cannot easily break or tear apart the locksets.

Many health facilities are concerned with wander management and patient monitoring. From simple key locks to regulated, electronic access, identifying a facility’s security needs and security door locations will dictate what electronic devices door sets need. To prevent unauthorized movement of minors, dementia patients and patients under surveillance, a facility may utilize self-closing, selectively secure doors with automatic locks that initiate when a banded patient approaches. This allows free movement of authorized staff and visitors. When you identify these specific door and hardware needs, you simplify coordination meetings with the electrical engineer since doors needing power were tagged during the user meetings.

Everyone notices the millwork on a nurse station and the floor pattern throughout a patient unit. Of equal (or greater, some will posit) importance, is the less obvious choice of door hardware – where not every door lock or hinge is created equal. Healthcare facility designers and hospital personnel take these selections very seriously though, and with good reason. The right hardware for the specific patient care environment can be a matter of keeping the patient on track for recovery as the right dosage of antibiotic or rigor in their physical therapy regime.