Our team at Array designed prefabricated exterior panels to clad the 473,000 SF medical center. Aside from one spot where a steel support was installed at the wrong elevation and resulted in an adjustment in the shop, costly rework in the shop was averted for the entire prefabricated façade. The key to the exterior façade’s success is the expected, well-heard mantra: communication. A design assist project delivery method guided the project, and plenty of planning pre-construction enabled the design to come to realization on site using as much prefabrication as possible. Let’s take a closer look at four tips to leverage design assist and prefabrication to minimize and potentially eliminate rework on healthcare projects

Our team at Array designed prefabricated exterior panels to clad the 473,000 SF medical center. Aside from one spot where a steel support was installed at the wrong elevation and resulted in an adjustment in the shop, costly rework in the shop was averted for the entire prefabricated façade. The key to the exterior façade’s success is the expected, well-heard mantra: communication. A design assist project delivery method guided the project, and plenty of planning pre-construction enabled the design to come to realization on site using as much prefabrication as possible. Let’s take a closer look at four tips to leverage design assist and prefabrication to minimize and potentially eliminate rework on healthcare projects

1. Preplan as much as possible.

Design assist coordination consisted of weekly work sessions during the detailing phase of shop-fabricated façade panels.

The architect, subcontractor, and construction manager were all at the table each week reviewing the shop drawings of the week that were marked up by the architect. Shop drawings for the prefabricated panels were painstakingly scrutinized to the ¼” since design drawings did not have the constructability nuances integrated. This included ¾” wide sealant joints and specific panel geometries that were unknown during the development of the design drawings but revealed during the subcontractor’s development. Reviews were conducted with equal respect around the table, and day-to-day players rolled up their sleeves until no uncertainty was left on the drawing board. “Moderate pain” preconstruction saved what would equate to “a lot of pain” and dollars during construction.

2. Prefab as much as possible.

The majority of the exterior was composed of the total 475 prefabricated panels of mixed finishes (EIFS, ACM, cultured stone). Exceptions were limited to areas of concrete masonry unit wall assemblies and areas where it proved too difficult to lift prefab panels into place, i.e. walls under any overhangs or canopies. Prefabricated panels included the already-easy-to-assemble penthouse enclosures, but we even made the installation of those more efficient with prefabrication. Typical panel modules were made as large as the flatbed truck and highway lane could safely hold with police escort. The panel subcontractor, Jersey Panel Corporation, was thankfully located only a couple underpasses away from the project site. The oversized panel allowed a single panel to encompass multiple finishes for increased control of finish transitions, less joints, and less install time.

3. Pros went beyond speed and quality.

Some smaller scaled positive aesthetic outcomes resulted from the accuracy of in-shop fabrication and preconstruction work sessions. Fine-tuned designed alignments were achieved in what could be considered a façade type that is not typically revered for its precision – EIFS and random cultured stone. The tops of all joints were aligned with centerlines of the next element – as is evident across the multiple materials and thousands of square feet at Inspira’s facades. This is seen not only across all prefabricated elements, but between prefab to field constructed, from wall to canopy, from concrete masonry unit wall joints to curtainwall and back to prefab walls. The accuracy of the prefab drawings was vetted by all parties at the table, creating a solid foundation for field-built scope to accurately work with.

4. Increase early pre-construction coordination

Early pre-construction coordination gave us the luxury of extra time, which in turn enabled the team to challenge what was expected. The architect was better positioned to have the subcontractor rethink typical details. Prefabricated panels can be somewhat stocky because they are products that can only be customized to a certain extent. They are composed of pre-tested assemblies that need to be maintained to hold their performance, and designed with economies of scale in mind, and with that, they can have some equally stocky aesthetics out of the box.

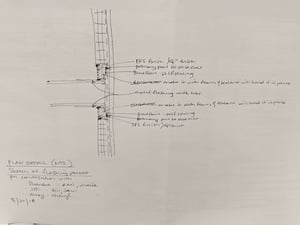

Typical details, such as how to terminate a parapet against an adjacent 90 degree surface, often need refinement. Metal flashing is the expected material when a neighboring parapet terminates into the adjacent 90 degree surface, but our building was not of the metal patchwork aesthetic. This was especially important since the monolithic presence of stone (although faux) would be undermined with a metal patch whenever intercepted by parapets. Building respect and an air of equal collaboration enabled all players to freely get out their pencils and reconsider what is ‘easy.’ Our collaboration resulted in a detail that drove the typically exposed metal flashing under the clad (faux) stone. It required some come back in-field work on shop fabricated panels, but ultimately resulted in the desired formidable stone walls and a better seal to the weather barrier, adding value to both form and function.

In closing

This is a story of construction that I hope wears the efforts put into it on its sleeve. Effective, constant collaboration with our design assist partners from the onset in combination with prefabrication resulted in the proper execution of details, design intent, efficiency, and enclosure that got it right on first install.

Learn more about Inspira Medical Center Mullica Hill by reading our new design book.