5S is a lean tool typically implemented in the manufacturing environment. So, how can an architecture firm use this lean tool in the office environment? First, let me explain what 5S is exactly and why we would want to use it in the first place.

The 5S philosophy, the goal of which is to develop a standard format, allowing for the easy detection of anomalies while minimizing motion, got its name from five tasks that lead to a more organized, standardized and disciplined workplace. In Japanese, each task begins with “S” and translates to an English word that also begins with “S.” Training typically presents it as a lean tool that is merely a way to keep an area tidy, but it's so much more than tapelines and shadow boards.

5S can be especially difficult to apply in an office environment, which lacks physical processing. However, there are some areas in an office that could benefit from it. Many videos showing individuals performing the process on a personal desk appear online, some of which are accurate representations of how it can reduce the clutter of unused articles and provide order for a jumble of folders and papers. Others go to the extreme of satirical demonstrations by creating tapelines for every object on the desk.

5S can be especially difficult to apply in an office environment, which lacks physical processing. However, there are some areas in an office that could benefit from it. Many videos showing individuals performing the process on a personal desk appear online, some of which are accurate representations of how it can reduce the clutter of unused articles and provide order for a jumble of folders and papers. Others go to the extreme of satirical demonstrations by creating tapelines for every object on the desk.

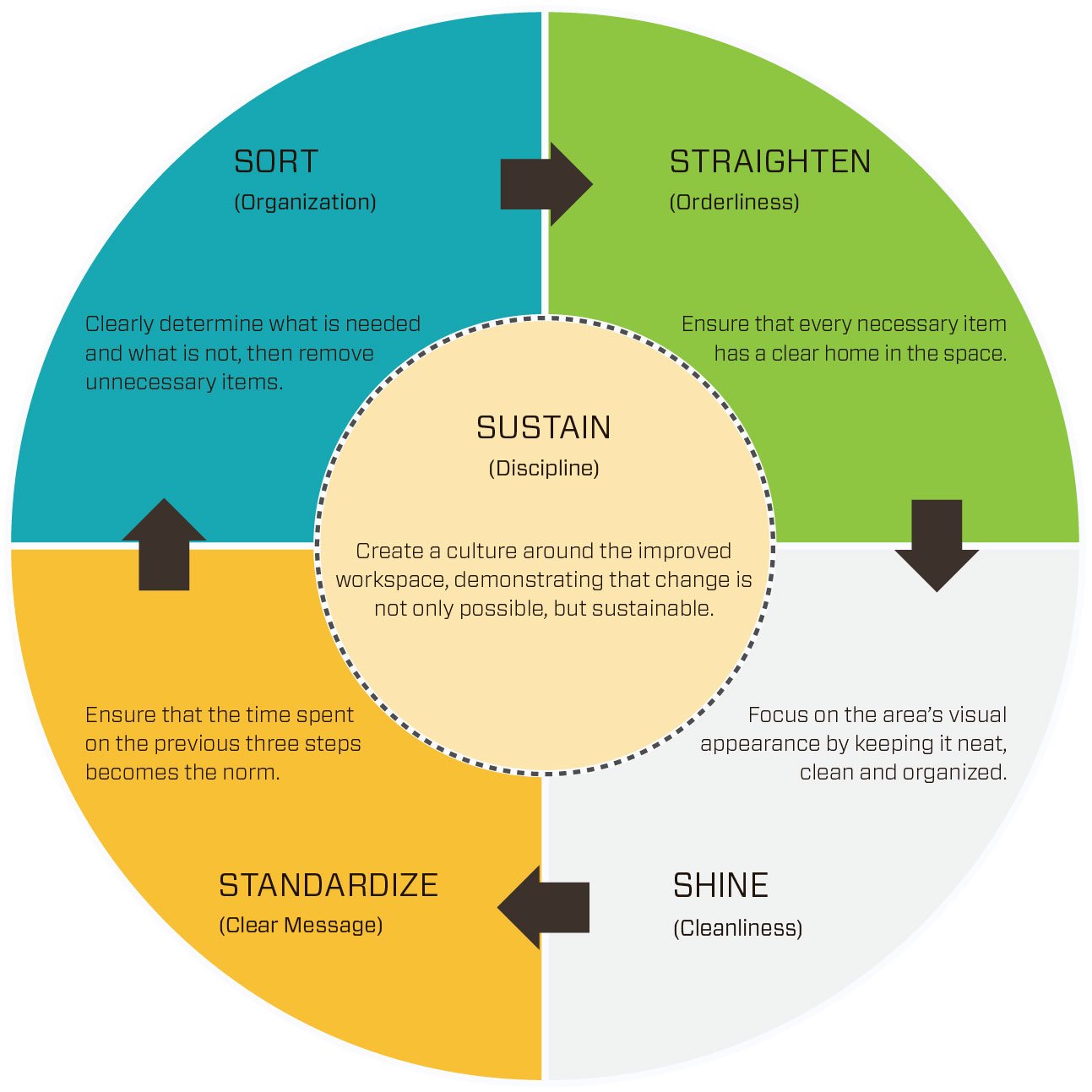

Remember that the goal is to create a more organized, efficient work environment where missing or misplaced objects are easily detectable and commonly used items are only an arm’s length away. Detailed below is an application of the process in the office environment along with definitions for each “S.”

seiri (整理) = “sort” | In this first step, the goal is to determine what is needed and what is not, typically using red tags to identify objects that do not belong. Sorting enables the removal of clutter, making necessary items easily accessible. Imagine an office supply closet. In it, there are small office supplies scattered across three shelves, along with IT equipment, reams of paper and digital cameras. Management recently decided that this closet would only be used for small office supplies and that a cross-disciplinary team should get together to clean it up. This first step helps the team separate all of the small office supplies from the other items. Objects that will not be stored in the closet are removed from the space and either discarded or placed in a different location.

seiton (整頓) = “straighten” | This next step ensures that every necessary item has a home in the space. It is clear where each object goes, and it would be painfully obvious if an object were missing from its place. Once this step is complete, every necessary item has a designated location. In our example, all of the small office supplies that will remain in the closet should be categorized so that frequently used items are placed where they can be accessed quickly. Often, baskets or bins are needed to keep small objects together and labels may be used to make finding objects easier.

seisō (清掃) = “shine” | Seisō, the third step, focuses on the visual appearance of the area. When all clutter has been removed from a space and objects are assigned specific places, the newly organized area should sparkle! Having a clean space will make people want to keep it that way. If you walk into a cluttered supply closet, what’s stopping you from leaving the scissors you’re returning anywhere you can find space on the shelf. If the closet is neat and organized, the proper location for scissors will be obvious. You will return them to the appropriate location, and the next person who needs a pair will be able to find them quickly and easily.

seiketsu (清潔) = “standardize” | Seiketsu follows; ensuring that the time spent on the previous three steps becomes the norm. When the space is standardized, there is a clear message about how a space should function and any abnormalities will stand out. In a standardized supply closet, to ensure there is never an over-abundance or scarcity of supplies, a Kanban system may also be used as part of the standardize step.

shitsuke (躾) = “sustain” | The trickiest step, shitsuke, or sustain, comes last. This final step creates a culture around the improved workspace. Without sustainability, the shiny new space will soon lapse into the cluttered supply closet. Sustaining the changes drives the culture of improvement forward, demonstrating that, not only is change possible and sustainable, but also that it is helping people work more efficiently.

Performing 5S may seem like a simple project with five easy steps, but it actually encompasses so much more. Problem solving can be performed more effectively after completing this process. Identifying discrepancies in the new standardized supply room becomes much simpler if every object that belongs in the room has a place. When you group together and clearly identify each supply item, a more stabilized approach to inventory will likely develop. It is a powerful tool that goes far beyond simple “housekeeping” the steps seem to describe. As with many things we learned from Toyota, it’s not just about the tool but the philosophy behind it.