In an effort to provide a full spectrum of health services to each of its communities, Mercy Health System identified Behavioral Health as a priority service line for improvement. As mentioned in the previous post, the System sought to bring parity to their hospitals and redesign their behavioral health services system-wide.

Based on market research, as well as existing and planned patient beds, the System’s behavioral health team provided estimated bed counts and proposed square footage requirements for each facility. These estimates were provided to vendors for bulk pricing. The request for proposal to the vendors of each item required that they deliver the goods on an ‘as needed’ and ‘on time’ basis. Each vendor was responsible for storing, handling and/or delivering materials, as well as for manufacturing timing. This protected the owner and contractor from risk associated with each.

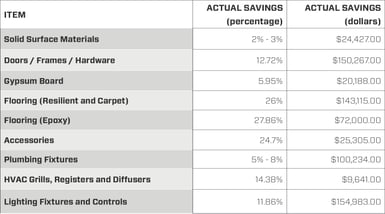

The base-unit price proposal from each vendor was for the known quantities of the first project. The unit price variance, depending on quantity chosen, shows the achieved savings when purchasing each item in bulk. Each awarded vendor will be compensated per the unit price associated with the actual quantity of product after design and procurement is completed. Each project is awarded purchase orders, which allocate, on track, the appropriate cost to each contract/location.

Danis was able to involve the local subcontractors in sharing the procurement risk, further protecting the client and aligning best practice construction with today’s market. This was especially evident in the Mechanical, Electrical and Plumbing trades. With careful coordination and clear communication between the Construction manager, designers, subcontractors and vendors, procuring the correct quantities ensures the correct accessories and options are included and available when needed. The post-award examination of the process showed that market factors, short schedule and the guarantee of the quantity ranges led vendors to agree to lock-in today’s rates for items that were not ordered immediately. This led to significant savings.

The procurement process is an important part of any subcontractor’s business model. When subcontractors build relationships with material supply vendors, they gain bid advantages by leveraging those relationships or utilizing buying power within their markets that others can't duplicate.

This process leads to both bid advantages and increased margins. Through open and clear communication, we were able to navigate the process and ensure that subcontractors, material suppliers and their business models were respected. In post-award and post-construction surveys, subcontractors stated that they felt the process was transparent and fair.

By committing to a preliminary schedule for each project with an estimate of final construction on the last project by December 2015, the risk of escalation was also the responsibility of each vendor. Clearly communicating the payment and procurement terms and conditions to the material supply vendors enabled them to provide proposals that were more competitive due to the definitive payment terms and the ability to project cash flow accurately. After assessing the final cost and receiving feedback from the vendors involved, it is evident that the client realized significant economic benefit by combining projects, increasing buying power and bulk purchasing the fixtures, equipment and materials.

Nick Hoyng is the Director of Business Development for Danis Building Construction Company. Brian Currin is a Project Manager with Danis.